About Us

Plastics Northwest, Inc. is a custom design and manufacturing company specializing in injection molded plastics, pad printing and assembly.

Our mission is to exceed expectations in quality, delivery and cost. To achieve this goal, we begin every potential project with a complete review of the part design, mold design, manufacturing process, materials and material additives. We will make recommendations with a manufacturing proposal.

Attention to our customer’s needs. Sincere desire to improve the current product and process, and our unfailing commitment to quality have been the keys to success for more than 30 years.

I invite you to take a moment to view our site and learn more about the exciting things happening in our Company. My professional staff and I are available to receive your call or email should you need more information.

square feet

years of manufacturing

injection molding machines

Services

At Plastics Northwest, Inc., we provide our customers with a wide variety of services to assist with their manufacturing needs accomplished at one location with one vendor.

We maintain a large number of injection molding machines to mold plastic parts in any size, material or color from a fraction of an ounce to over 13 pounds. Below is a partial list of our machines.

56 ton, 1.7 ounces, Sumitomo with robot sprue picker

85 ton, 6 ounces, Milacron

100 ton, 7.2 ounces, Sumitomo

120 ton, 9.6 ounces, Milacron

125 ton, 9.6 ounces, Milacron

210 ton, 30 ounces, Mitsubishi

220 ton, 17 ounces, Milacron

280 ton, 24.5 ounces, Sumitomo

310 ton, 58 ounces, Milacron Wide Platen

400 ton, 41 ounces, Milacron

560 ton, 61.3 ounces, Sumitomo

720 ton, 162 ounces, Goldstar

950 ton, 213 ounces, Goldstar

Our Facilities

Plastics Northwest, Inc. operates a state-of-the-art facility located in Vancouver, Washington. Our machines range in size from 50 – 950 tons of clamping power to efficiently mold most sizes. We provide world-class engineering, mold design, part design and material selection. Finished parts meet the highest standards. We manufacture, assemble, print, trim and sonic weld a finished product from raw materials to completion. We deliver products to you or to your customer including blind shipping, specialized packaging and documentation.

Products

Construction

Food packaging

Heavy equipment

Hospital and medical

Landscaping Dec-O-Vents

Playground equipment

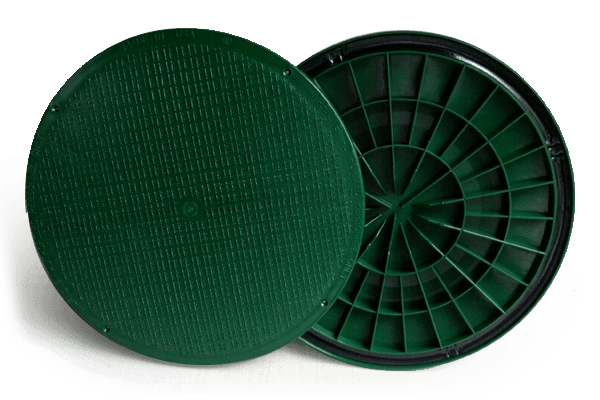

Septic tank components

Sportsman and outdoor

Septic tanks can be an expensive investment. Our proprietary designed lids are built for long-lasting installation.

Contact Us

Please call our Customer Service Department during business hours 8 am to 5 pm Pacific Standard Time (360) 823-0505. After hours, email us at plasticsnw.com including contact information about your project.

2851 Lower River Road

Vancouver, WA 98660

Phone (360) 823-0505

Fax (360) 823-0506